clamcleat.com uses cookies to ensure we give you the best experience on our website. By navigating our site, you agree to allow us to use cookies, in accordance with our Privacy Policy

CL258 Racing Fine Line (Starboard)

| Technical Details | Metric | Imperial | |

|---|---|---|---|

| Rope Diameter | 3 - 6mm | 1/8 - 1/4" | |

| Material | Aluminium | Aluminium | |

| Hole Centres | 49mm | 1 15/16" | |

| Length | 70mm | 2 3/4" | |

| Width | 21mm | 13/16" | |

| Height | 14mm | 9/16 | |

| Bolt Size | M4 | #8-32. 5/32" | |

| Screw Size | 4.2mm | No 8 | |

| Weight | 19gms | 0.7oz |

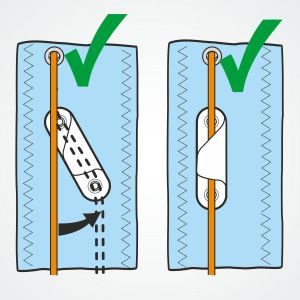

The tooth design of the Clamcleat® CL258 Racing Fine Line (Starboard) allows a quick, positive lock that is easy to release. Add this to its' low profile and ability to hold high loads, makes it an ideal cleat for adjusting leech lines on larger sails. Use a backplate when riveting a cleat onto fabric to prevent the rivet pulling through. It can be mounted in two positions and can be sewn or riveted to the sail. The CL258 is usually ftted to the Port side of a sail, when used for tensioning leech lines. See the fitting diagrams above.

The CL258 is also used for industrial blinds and as a low profile deck cleat on dinghies.

Manufactured from aluminium for light weight and durable performance the CL258 is available in two finishes:

1. CL258 has a silver stove enamel finish for a cost effective, high quality coating.

2. CL258AN has a hard anodised finish to give the ultimate hard wearing surface. (Note that alloy cleats should be sewn onto carbon fibre sails, to avoid corrosion.)

The nylon version of this cleat is the the CL212.

For the other side of a sail please look at the CL259.

For light coloured sails, use the silver CL258 plus CL212BP white backplate.

For dark & carbon sails use the hard anodised CL258AN plus CL212BP-B black backplate.

The CL212A is a shield to help prevent rigging snagging in the cleat .

For a similar cleat with a fairlead, see CL241.

Q: Does Clamcleat® make a port version of the CL258?

Ans: Clamcleat® port version of the CL258 is CL259.

Q: Does Clamcleat® make products for fitting to a sail?

Ans: Clamcleat® make a range of products suitable for fitting to sails both port and starboard side. The cleats are suitable for ropes from 0 to 6mm and are available in Nylon and Aluminum.

Q: Does Clamcleat® make a Leech cleat?

Ans: Clamcleat® make a range of Leech cleats for fitting to sails both port and starboard side. The cleats include CL212, CL214, CL221, CL273 and CL281.

Q: Does Clamcleat® make a sail edge cleat?

Ans: Clamcleat® make 2 different sizes of sail edge cleat CL267 and CL269.

Q: How do you secure a cleat to a sail?

Ans: Clamcleat® has two options for securing the sail cleat to the sail which are Sewn and rivetted. Backing plates and rivets are available.

Q: Why does Clamcleat® not publish safe working loads (SWL) or break loads for its cleats?

Ans: The quality, type and style of the rope or cord plays a major role in the performance of the cleat. Normally the better the quality of the rope the greater holding power, also some cleats are designed to slip once they exceed the desired holding load as a safety feature including securing fabrics such as sunshades or covers.

Q: Do you get a better performance with an Aluminum cleat?

Ans: Aluminum cleats do not improve the performance of the cleat, but they can achieve higher holding loads and they also might improve the lifespan of the cleat especially if the rope will be in contact with the teeth whilst the rope is being pulled through during adjustment.

Q: What different coating are there for the Aluminum cleats?

Ans: The standard coating for the cleat is a Stoving Aluminum silver enamel coating. For extra protection from corrosion and a high-tech appearance the cleats are also available in a dark grey Hard anodized finish. The part no in suffixed with “AN” to identify the hard anodized finish.

Q: What is the best way to fix an aluminum cleat into a carbon fiber spar?

Ans: You need to create a barrier between the aluminum cleat and the carbon fiber surface to stop electrolytic de-composition. The barrier can be created by cutting a thin shim of plastic to the shape of the cleat and drill the fixing holes (the retail card the cleat is sold on is ideal to use as the shim), also use aa inhibitor or anti corrosive jointing compound such as Duralac on the fixing.

Q: How long should a Nylon cleat last?

Ans: This really depends on the usage, the quality and age of the rope used etc. so is very difficult to gauge. The ultraviolet rays will discolor the cleats over time and in very sunny climates may affect the life of the cleat. In extreme climates the life expectancy should be 10 -15 years depending on usage and in more moderate climate 20 + years.

Q: How long should an Aluminum cleat last?

Ans: This really depends on the usage, the quality and age of the rope used etc. so is very difficult to gauge. The ultraviolet rays will discolor the cleats over time and in very sunny climates may affect the life of the cleat. In extreme climates the life expectancy should be 10 -15 years depending on usage and in more moderate climate 20 + years.

Q: Can I fit my cleats using pop rivets?

Ans: Using pop rivets to fit your cleat is a tidy quick way of securing the cleat. Ensure the pop rivet is at 90 degrees to the cleat when fixing and with certain smaller cleats the head of the pop rivet gun will not sit onto the pop rivet when in place so you will require to add a spacer between the gun and the rivet.

Q: What type of rope or cord will give the best performance on my cleats?

Ans: In our experience a braided good quality rope gives you the best holding performance.

Q: Is there any maintenance required to a cleat to keep it performing well?

Ans: We would recommend flushing the with fresh water as often are you can.